What are the advantages and disadvantages of CNC machining?

What are the advantages and disadvantages of CNC machining?

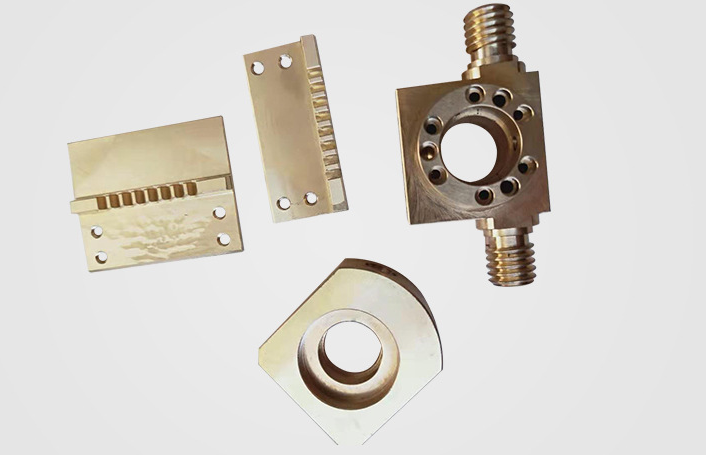

With the development of the economy, the factory is becoming more and more industrialized, many factories have long used CNC machining for operation, CNC machining is a new processing technology, the main task is to program the processing program, the original manual work into computer programming, can be in accordance with the technician in advance programmed program automatically on any product and parts directly processing. So what are the advantages and disadvantages of CNC machining? The following is the sharing of the editor of Peike Automation:

First, the advantages of CNC machining:

1. CNC can be processed automatically

CNC machining usually refers to precision machining that is digitally controlled by a computer. Therefore, it can be controlled by the program instructions of the CNC machine tool, and the entire processing process is carried out automatically according to the program instructions. The machine tool has a high degree of automation, which greatly reduces the labor intensity of workers.

At present, many CNC machines can run unattended throughout the entire machining cycle, freeing up the operator to do other tasks. This brings several side benefits to CNC users, including reduced operator fatigue, fewer errors caused by human error, and consistent and predictable machining times for each workpiece.

2. CNC machining accuracy is high

The second major advantage of CNC technology is the consistency and precision of the workpiece. The typical accuracy of today's CNC machine tools has reached two to four thousandths of an inch or 0.05 to 0.10 millimeters, and the repeatability is close to or better than eight thousandths of an inch or 0.02 millimeters. This means that once a program has been validated, it is easy to produce two, ten or a thousand identical parts with the same accuracy and consistency. Mass production can be realized, and the product quality is easy to control.

3. Strong flexibility in CNC machining

Since these machines are run by computer programs, running different artifacts is as simple as loading different programs. This also comes with another benefit, which is fast conversion. Since these machines are very easy to set up and run, and can easily load programs, they have a very short setup time.

4. CNC machining efficiency is high

CNC machining can carry out multi-coordinate linkage and can process complex zero points. When the shape and size of the parts need to be changed, only the CNC program needs to be changed, saving production preparation time.

5. It can process complex profiles that are difficult to process by conventional methods, and can even process some unobservable processing parts.

6. In the case of multi-variety, small batch production, the production efficiency is higher, which can reduce the time of production preparation, machine tool adjustment and process inspection, and reduce the cutting time due to the use of the best cutting amount.

Disadvantages of CNC machining

1. High technical requirements for operators and machine maintenance personnel

2. The CNC machining route is not easy to control, and it is not as intuitive as ordinary machine tools.

3. The purchase cost of machine tools and equipment is more expensive.

The above advantages and disadvantages of CNC machining are shared here, CNC machining can greatly reduce the number of tooling, even if the processing of parts with complex shapes does not need complex tooling, if you want to change the size or shape of the parts only need to change the processing program of the parts.

Latest News

Contact Us

Name: Mike

Tel: +8613662873457

E-mail: sales@bolusigroup.com

Whatsapp: +8613662873457

Add: No.10 Sanjiang Industrial Zone,Hengli Town,Dongguan City,Guangdong Provice,China

CHINESE

CHINESE ENGLISH

ENGLISH

WhatsApp

WhatsApp  Mail inquiry

Mail inquiry